Reach trucks FM-X

Top-level precision.

- 13-metre lift height with high residual load capacity

- Active load stabilisation (ALS)

- Holistic ergonomics concept

Request to: FM-X

Please fill out the form below. We will get back to you as soon as possible.

The FM-X is always more than just a fork ahead of the rest. Thanks to active load stabilisation (ALS) you can deal with the next goods transport while others would still be waiting for the mast to stop vibrating.An automatic equalising pulse provides a fast and effective way of stopping the vibrations from occurring at great heights, reducing the waiting time at the shelf by up to 80 per cent. The result is a significant increase in turnaround speed.

Furthermore, the available storage space can be used more efficiently with the FM-X than ever before; the high residual load capacity means that the reach truck can lift loads of up to 1,000 kg to an incredible height of 13 metres.

The holistic ergonomics concept ensures relaxed, comfortable and safe work throughout each shift. Foot plates, steering wheel, seat – all these elements can be adapted in various ways according to the working situation, build and preferences of the driver.

Numerous other details, such as a driver’s seat with optional tilting technology as well as STILL’s exclusive sideshift mast, make the FM-X the ideal warehouse organiser – from the handling of high shelves to long-distance transport and the replenishment of pallet goods.

Simply easy

- Stable forklift mast with high residual load capacity for lift heights of up to 13 metres (1,000 kg)

- Powerful acceleration combined with high travel speeds of 14 km/h and lifting speeds of up to 0.50 m/s

- Sufficient energy for any use, thanks to battery capacities of 360 Ah to 930 Ah

- Lasting energy for multi-shift operation: high battery capacity and optional battery change over the side

- Top availability: The lithium-ion battery bundles a lot of energy and can be quickly and easily opportunity charged

Simply safe

- Cushioned driver’s seat to reduce impact when driving over uneven surfaces

- Seat can be adjusted to the best ergonomic position, thanks to proportional adjustment of the seat and foot plate

- Relaxed view upwards and beyond goods, thanks to unique comfortable reclining seat

- Easy to operate all functions without grasping, thanks to joystick or fingertip operation

- Easy storage and retrieval with the Easy Target lift height pre-selection system

Simply connected

- The large step and handle make it safe and easy to get in

- Versatile, flexible access control with FleetManager 4.x

- Extremely safe to drive round bends with curve speed control depending on steering angle

Simply powerful

- High reloading performance: reduced mast vibrations, thanks to Active Load Stabilisation (ALS) for greater lifting heights

- OPTISPEED reduces mast vibrations to a minimum for medium lifting heights and enables quick goods handling

- Great view of goods without being disrupted by hydraulic lines on the fork carriage, thanks to its unique sideshift mast

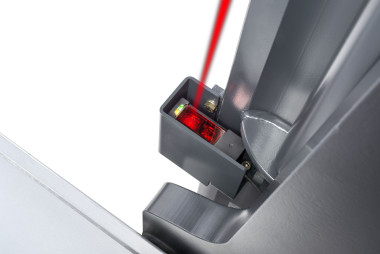

- Top precision right from the first millimetre thanks to the optical lift height sensor

Simply flexible

- Suitable for even the most narrow working widths, thanks to the reach truck concept

- Thanks to its particularly narrow chassis, the FM-X N is suitable for use in block storage and one-way shelving

- The FM-X W version allows picking up industrial pallets lengthwise between the straddle arms

- The FM-X EW version allows picking up industrial and Euro pallets crosswise between the straddle arms

Forklift driver assistance systems

Sharpening all senses: we can support you with our wide range of smart driver assistance systems and functions which will make your day-to-day work significantly easier. You will be able to drive in a safer, more comfortable, efficient and fatigue-free manner – in every driving situation.

Safety first: digital guided Pre-Shift Check

With the Pre-Shift Check in the on-board computer STILL Easy Control STILL achieves a new level of safety for the driver and the truck: before the start of each shift, or at user-defined intervals, the driver must confirm the operational capability of the truck via the on-board computer before he can put the truck into operation with all its functions.

The customer is free to choose the criteria of the safety check. In addition to the standard query, several individual queries can be stored in the display of the on-board computer. And if an answer is negative? The customer has all options.

For example, he can define in the system that the performance of the vehicle is automatically limited if a query shows a negative test result.

Learn moreSafety in the warehouse is increased thanks to an acoustic signal during reversing. Colleagues are therefore able to notice the forklift truck even if they have their back to it.

Learn moreWith the breathalyser, the driver has to carry out an alcohol breath test before they can operate the truck. The truck is only released once the test has been passed. The advantage of the test is that it is very difficult to manipulate the results and can help to prevent accidents. Thanks to interchangeable mouthpieces, it is hygienically safe.

The broadband alarm is an audible alarm that emits a broadband signal tone. Over longer distances, the tone is drowned out by ambient noise. However, in the immediate environment the noise and thus the source of danger are very easy to locate. This increases awareness of the truck and prevents accidents.

The protective grille roof is available in a low or high version, according to the height of the passageways. It protects the driver from falling loads.

Keeping the goods in place: the load backrest stabilises the transported goods at the fork carriage back so that they can be securely transported from A to B.

Learn moreA flashing, warning or rotating light increases safety at the warehouse and makes other employees working in the warehouse aware of the forklift truck via a flashing yellow light signal. If preferred, this can be set to only light up when reversing. The use of this light increases safety particularly in areas where hearing protection is required to be worn. The rotating light is available in various designs and can be mounted on or behind the overhead guard.

Learn more

Access control perfectly integrated into the truck with different types of access authorisation for one or more trucks: with FleetManager 4.x you are free to choose the type of access authorisation for one or more trucks: chip, FleetManager card, your personal plant ID card or a PIN.

Thanks to the smart auto-logout function, the trucks are automatically deactivated after a freely selectable period of time – this also increases safety.

If desired, you can limit the usage of your forklift truck to specific persons or groups of persons via access authorisation. Select whether the release of the truck should be carried out using a key switch or via a digicode system with ten configurable access codes (or PINs).

Learn more

Digicode systems (PIN) are an easy way to prevent unauthorised use of the truck. The truck can be started up quickly and easily, simply by entering the PIN code. This allows the user to limit access authorisation to specific individuals or groups. It is possible to configure up to ten PIN codes.

More information

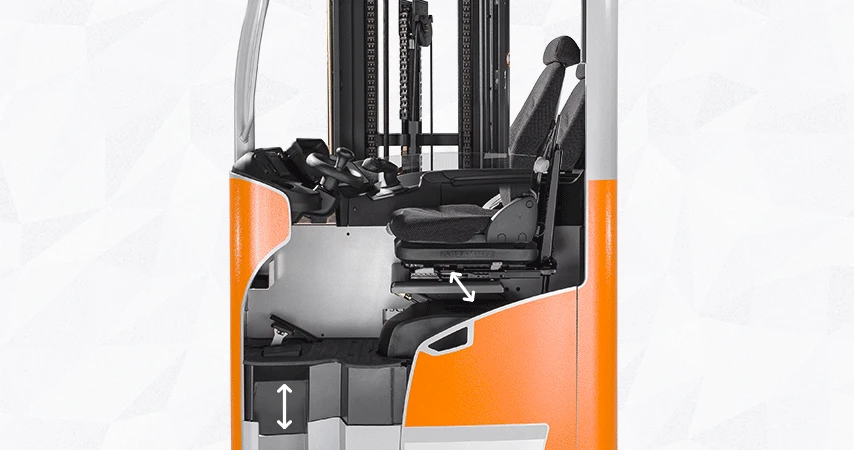

Sit back and relax:

The optional tilt seat for the FM-X noticeably increases the ergonomics of the driver’s work space. The tilt seat is easy to operate and protects the driver's back and neck while working. It also improves visibility when climbing in and out.

Learn moreOptimal visibility at all times: the optional panoramic overhead guard with armoured glass window provides improved visibility when storing and retrieving goods. It works entirely without the need for struts and of course meets all the safety standards of a standard overhead guard.

Learn more

Always at the right height:

The height of the seat and the foot plate can be proportionately adjusted. Individual comfort settings can therefore be configured for different operators to ensure fatigue-free driving. The shock absorption in the driver’s work space protects back muscles on uneven floors and at thresholds.

Learn more

No wobble here

The FM-X is always more than just a fork ahead of the rest. Thanks to Active Load Stabilising (ALS) you can be dealing with the next goods transport while others have to wait for the mask to stop vibrating. An automatic equalising pulse provides a fast and effective way of stopping the vibrations from occurring at great heights, reducing the waiting time at the shelf by up to 80%. The result is a significant increase in turnaround speed.

Learn moreAutomatic speed adjustment for curves

The speed limiter controlled by steering angle reduces possible damage to goods by adapting to an appropriate cornering speed. This assistance function is available for various forklift trucks and warehouse technology devices, and regulates the driving speed automatically according to the steering angle. In other words, the driver doesn’t need to worry about speed when cornering. The truck automatically decelerates precisely as much as necessary for the operator to drive as safely but as quickly as possible.

Learn more

Hit the bullseye at the touch of a button

Thanks to Easy Target Plus, the goods can quickly and precisely be positioned in the desired shelf level – easily at the touch of a button without manual height corrections.

Advantages to you:

- High degree of safety for the driver and the goods

- Guided operation via the display assistant – simple operation even for inexperienced drivers

- Rapid selection of the desired shelf level

- Individual adjustment to all warehouse conditions

Seeing instead of estimating

With the help of the optional LED lift height sensor (standard on the FM-X), the lift height display ensures maximum precision from the very first millimetre. This means that operators always know the height of the fork tips and can navigate precisely to avoid touching the rack when picking up the pallet. The system works with a repeatability of less than +/- 5 mm and the lift height is permanently shown to the drivers on the display.

The ceiling sensor detects low ceiling heights and prompts the driver to reduce their speed in order to promote general work safety in the warehouse. It comprises an ultrasonic sensor on the roof of the truck, which detects ceilings up to a height of 20 m. Depending on the sensor signal, the maximum speed is controlled, whereby the standard speed is 6 km/h.

Who can use which forklift truck for which area of application? How fast may a certain driver travel in the industrial truck?

The solution: our smart driver profiles in FleetManager 4.x. This web-based application allows the features of the truck to be adapted to the operator’s requirements, such as a reduction in travel, lifting or tilting speed or automatic activation of the lights.

More information Learn moreThe right driving programme for all requirements: the operator can choose between three established and two freely configurable driving programmes in the three operating modes: Blue-Q, normal and sprint mode. The driving programmes can be chosen according to the situation in order to achieve the maximum performance or energy efficiency.

Intelligent autopilot: the forklift’s Blue-Q (blue button) efficiency mode is activated at the touch of a button. An intelligent optimisation characteristic in the drive saves energy precisely where it is not impacted by the work process.

Up to 10% savings in energy consumption depending on the use profile and forklift equipment.

Learn moreIn addition to the lift height display, there is a range of lift height pre-selection systems available for the STILL FM-X reach truck. Manual lift height selection is available as standard. The Easy Target and Easy Target Plus systems are available as options.

Easy Target enables fast and precise positioning of the forks at the desired shelf levels, without the need for manual height corrections. This increases safety for both the driver and the goods. Up to eight areas, each with 20 levels, can be programmed. From 150 kg, the forklift truck is able to independently determine whether the operator wishes to store or retrieve loads and thus consider the pallet free lift accordingly. Another option available is Easy Target Plus, which also ensures that the fork tilt is in the neutral position. How you benefit: Individual customisation to suit all warehouse conditions, high degree of safety for the driver and the goods, and guided operation via the display assistant – also, for less experienced drivers, the shelf level can be selected in a matter of seconds.

Learn moreLet nothing slide, even at great heights: the pallet is moved to a 90° position at the touch of a button. This makes extending and retracting the forks from the pallet a breeze even at the top shelf levels.

Learn moreMaximum handling capacity: STILL OptiSpeed

The package comprises comprehensive hardware and software assistance systems which optimise the movements of the truck regardless of the load. This significantly increases handling capacity. OptiSpeed uses software to determine optimum fork and travel movements depending on the lifting height. The system offers continuous adjustment of the driving speed in the aisle, independent of the lifting height. This ensures added volume capacity, comfort and safety.

The OptiSpeed 3.3 variant combines the advantages of previous variants with a weight sensor: in addition to the visual and acoustic signals when specific limit values are reached, a travel and lift stop is triggered when the permissible load weight is exceeded. The system calculates ideal transport movements and optimises them based on the lifting height and load. That enables higher speeds on empty runs or when loading and picking.

Learn moreProcess safety at every lift height

The OptiSpeed driver assistance system reduces mast vibrations to a minimum for medium lifting heights and enables quick goods handling.

OptiSpeed cannot be combined with the ‘Active Load Stabilisation’ driver assistance system.

Learn more

The forklift truck travels at creep speed (5 km/h) with a defined lift height. This significantly reduces the risk of an accident as the driver has sufficient time to react promptly in the event of a hazardous situation.

Learn moreLeave nothing hanging on the balance: the system integrated in the FM-X reach truck virtually eliminates the risk of damaging goods when lifting pallets. The advantage of the shift and lowering lock is that pallets that have been lifted crookedly or diagonally lie on the wheel arms when they are lowered, and will therefore be tilted or pushed when pulling in the fork. The operator must always approve this for safety and is advised to check that the goods have been picked up correctly.

Learn more

Autostop before ground contact:

When forks hit the ground, it's not pleasant for the ears, the floor or the forklift. But on the other hand, would it not be very pleasant if this would not happen in the first place? That's exactly why we developed the electric fork wear protection for you. When the assistance system is activated, it ensures that the forks cannot touch the ground during lowering. Shortly before that, they stop automatically - exactly so that you can thread them perfectly into the pallet. Forks dragging on the ground due to accidental startup in the lowered state are also a thing of the past.

Learn more

The automatic parking brake is applied automatically or at the push of a button, and prevents the truck from rolling. The electrohydraulic spring-loaded brake locks whenever the truck stops.

Forks up, speed down:

More safety, less product breakage and ensuring proper vehicle use - these are the benefits offered by the Speed Reduction assistance system when the fork carriage is raised. As soon as the forks reach a height of 500 mm (or another defined threshold), the speed of the vehicle is automatically reduced. Even if a driver forgets that he should not drive with the load raised, the assistance system slows him down, guaranteeing safe handling of the load and vehicle.

Learn moreThese LED headlights improve the lighting conditions to the sides of the tuck and reduce the glare effect as they do not reflect off the mast from behind. This way, higher rack areas are also illuminated.

Fulfills lifting height requirements at the push of a button:

Smooth and jerk-free lifting and lowering operations become a reality with the mast transition damping and end stop damping. The assistance system automatically adjusts the lifting and lowering speed before the transition points of the mast. As a result, the inner masts glide smoothly out of the outer mast and back again, protecting the load from jerking. The system also automatically adjusts the speed before the lifting stops are reached, so that the end position is also reached smoothly and without jerking.

Learn more

Everything in view, all the time: the FM-X can optionally be equipped with a camera system which significantly facilitates operation and improves visibility.

Learn more

The camera systems for fork carriage, outer mast and rear offer improved visibility and thus help to prevent collisions with the warehouse infrastructure, as well as personal injury. The camera, which is attached to the truck according to its position, improves the driver’s vision of the environment by displaying an image on the driver’s monitor of everything that is captured by the camera in front and behind the truck.

The panoramic mirror, which can be mounted on the left or right side of the truck, improves visibility and reduces the size of the blind spot by expanding the field of vision. Drivers are able to get a quick overview of what’s behind them, allowing them to work more safely.

Safe operation at all times: the LED daytime driving light ensures that the forklift truck is always clearly visible even in darker areas. A daytime driving light is available for various trucks.

Learn moreDownloads

The document provided for download is the updated version of the operating instructions for the standard truck. It does not include descriptions of customer options (Customer Option). For a concrete truck, please request the respective specific manual according to the serial number and the year of production from the STILL spare parts service.

| Model | Maximum capacity (kg) | Maximum lift height (mm) | Overall width (mm) | Travel speed (km/h) | Battery voltage (V) |

|---|---|---|---|---|---|

| FM-X 10 / Li-Ion | 1.000 | 7.000 | 1.270 | 14.0 | 48 |

| FM-X 10N / Li-Ion | 1.000 | 7.000 | 1.140 | 14.0 | 48 |

| FM-X 10 iGo | 1.000 | 7.000 | 1.440 | 6.0 | 48 |

| FM-X 12 / Li-Ion | 1.200 | 7.000 | 1.270 | 14.0 | 48 |

| FM-X 12N / Li-Ion | 1.200 | 7.000 | 1.140 | 14.0 | 48 |

| FM-X 12 iGo | 1.200 | 7.000 | 1.440 | 6.0 | 48 |

| FM-X 14 / Li-Ion | 1.400 | 9.800 | 1.270 | 14.0 | 48 |

| FM-X 14N / Li-Ion | 1.400 | 9.800 | 1.140 | 14.0 | 48 |

| FM-X 14W / Li-Ion | 1.400 | 9.800 | 1.470 | 14.0 | 48 |

| FM-X 14EW / Li-Ion | 1.400 | 9.800 | 1.670 | 14.0 | 48 |

| FM-X 14 iGo | 1.400 | 9.800 | 1.440 | 6.0 | 48 |

| FM-X 17 / Li-Ion | 1.700 | 11.800 | 1.270 | 14.0 | 48 |

| FM-X 17N / Li-Ion | 1.700 | 9.800 | 1.140 | 14.0 | 48 |

| FM-X 17W / Li-Ion | 1.700 | 11.800 | 1.470 | 14.0 | 48 |

| FM-X 17EW / Li-Ion | 1.700 | 11.800 | 1.670 | 14.0 | 48 |

| FM-X 17 iGo | 1.700 | 10.000 | 1.440 | 6.0 | 48 |

| FM-X 20 / Li-Ion | 2.000 | 13.000 | 1.270 | 14.0 | 48 |

| FM-X 20N / Li-Ion | 2.000 | 9.800 | 1.140 | 14.0 | 48 |

| FM-X 20W / Li-Ion | 2.000 | 13.000 | 1.470 | 14.0 | 48 |

| FM-X 20EW / Li-Ion | 2.000 | 13.000 | 1.670 | 14.0 | 48 |

| FM-X 20 HD / Li-Ion | 2.200 | 13.000 | 1.270 | 14.0 | 48 |

| FM-X 20 iGo | 2.200 | 10.000 | 1.440 | 6.0 | 48 |

| FM-X 25 / Li-Ion | 2.500 | 12.050 | 1.270 | 14.0 | 48 |

| FM-X 25W / Li-Ion | 2.500 | 12.050 | 1.470 | 14.0 | 48 |

| FM-X 25EW / Li-Ion | 2.500 | 12.050 | 1.670 | 14.0 | 48 |

| FM-X 25 iGo | 2.500 | 10.000 | 1.440 | 6.0 | 48 |