Very narrow aisle trucks MX-X VNA Trucks

Perfection in performance and comfort

- Optimum use of storage space: 18-metres lift height and highest residual load capacity

- Fast storage and retrieval: Active load stabilisation (ALS) to reduce mast oscillations

- Maximum possible working comfort: Spacious and flexibly adjustbale driver’s cabin

- Maximum travel speeds: Active Floor Compensation (AFC) compensates for uneven ground

Request to: MX-X

Please fill out the form below. We will get back to you as soon as possible.

Innovative technologies and smart modularity: The STILL MX-X VNA Very Narrow Aisle Truck (man-up) sets standards in handling capacity and user-friendliness. Developed to optimally handle any challenge, the MX-X scores with performance packages for every application profile. Thus you receive a truck precisely adapted to your individual requirements - from its dimensions to its technical features. The focus is on the operator: A spacious and flexibly adaptable driver's cabin, intuitive controls and smart assistance systems promise safe, comfortable and efficient work throughout a whole shift.

Driving speeds of up to 14 km/h, a lift height of up to 18 metres and the highest residual load capacity on the market make the MX-X a turnover champion in highly compacted warehouse worlds. Whilst the active load stabilisation (ALS) notably shortens storage and retrieval processes by up to 5 %, the mechanism of the turret head promises even shorter picking distances. Thanks to the fully welded auxiliary lift, the MX-X scores with maximum stability throughout its service life. The STILL MX-X high bay order pickers can be individually configured according to your requirements and will thrill you with their excellent functionality.

Simply easy

- Intuitive vehicle comprehension as well as safe and ergonomic operation thanks to the compact control panel with colour display, visual instructions and individual definition of favourites

- Customised and space-optimised design of the driver's cab with multifunctional bars and holders to fasten small load carriers in the driver's compartment

- Ergonomic order picking: small distance between driver's cab and load carrier guarantees optimum power transmission

Simply safe

- Twofold protection: sensor-controlled two-hand operation and electronic monitoring of the battery lock provide safety at work

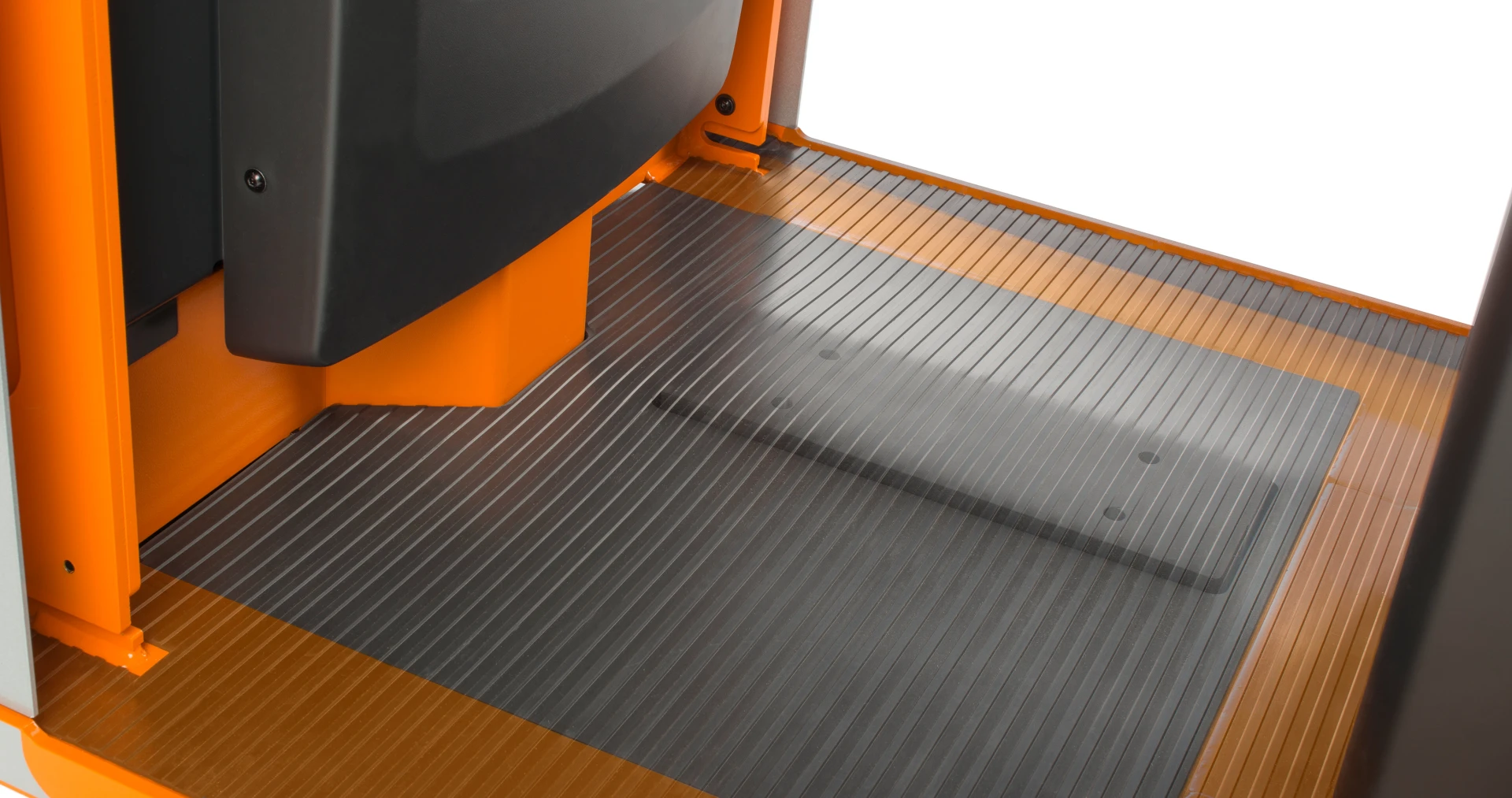

- The shock-absorbing floor in the driver's cab and the foot section facing the load side ensure a high level of user comfort and health protection

- Accident prevention with Rescue Alarm, Safety Light and the optional iGo pilot safety function: the alarm system reacts sensitively to abnormal driver behaviour in narrow aisles, the lighting system increases the vehicle's visibility to third parties, and the pedestrian protection system (PPE) prevents accidents caused by carelessness

- Continual high performance at a consistently low noise level: particularly quiet drive and lift motors ensure minimal noise impact on the driver

Simply connected

- Minimise errors and increase throughput at the same time by using the iGo pilot navigation assistance system for automatic approach to the shelf

- Compact overview of all relevant vehicle information in the STILL neXXt fleet web application

- Optimisation of the flow of goods through uncomplicated connection to the company's own warehouse management system (WMS) with the iGo pilot navigation interface

Simply powerful

- Maximum turnover rates through configurable performance packages. In addition, various OptiSpeed options are available to increase performance, e. g. active load stabilisation (ALS) when operating the push function

- Maximum storage density: thanks to the massive chassis, the MX-X has a particularly high residual load capacity and can store even heavy goods high up

- Particularly high degree of space utilisation due to the lifting height of more than 18 metres

- Compensation of uneven floors even at high travel speeds thanks to Active Floor Compensation (AFC) as a cost-effective alternative to floor renovation

- Absolute availability: can be used with various batteries (lead-acid and lithium-ion) in 48 V and 80 V, and thus a real power pack even in multi-shift operation

- In the Blue-Q efficiency programme, the MX-X also saves energy at the touch of a button - without any drop in performance

Simply flexible

- Customised very narrow aisle trucks with individually configured vehicle dimensions and cabin variants enable high warehouse density and a high degree of utilisation diversity for all requirements

- High functionality in goods accessibility: optional tiltable side barrier facilitates ergonomic access to goods up to the last item

Forklift driver assistance systems

Sharpening all senses: we can support you with our wide range of smart driver assistance systems and functions which will make your day-to-day work significantly easier. You will be able to drive in a safer, more comfortable, efficient and fatigue-free manner – in every driving situation.

The visual warning system for fewer accidents

The blue warning light, STILL SafetyLight 4plus, significantly increases work safety in areas which are confusing or full of bends. The blue light spots are projected approx. 5 m in front of and behind the truck and warn people about the approaching truck to prevent impending collisions.

Learn moreSix in one sweep

Optimised braking paths: at the end of the aisle, the forklift truck decelerates gently in relation to the speed and lifting height, which increases handling capacity.

Automatic speed adjustment: in defined zones, speed adjustments can be set automatically based on the ground conditions.

Height limitation: The adjustable height limitation enables optimum use of the space below the roof for different hall heights.

Collision prevention: known obstacles can be defined. The driver does not need to memorise all particularities of the system and can concentrate on their work.

Aisle departure assistant: steering can be blocked for a defined stretch, e.g. when departing the aisle in order to prevent collisions.

Position selection: selection enables targeted movement into defined, often-used positions such as at transfer points.

Learn moreWith the mobile personal protection system from STILL, you are on the safe side when it comes to protecting people in narrow aisles. Sensitive safety scanners on the drive and load sides of the VNA truck monitor the route and reliably detect people in the aisle. Thanks to the latest scanner technology, the STILL PPS meets all legal requirements for occupational health and safety and workplace regulations - in a lean and efficient way.

Learn moreThe smart rescuer in an emergency: if the operator performs an atypical action which suggests a medical emergency, an acoustic and optical emergency signal will sound to alert colleagues to the situation.

Learn moreThe predictive braking system reliably detects static obstacles on the route in good time in aisles or warning fields at a distance of up to 8 meters and triggers the truck to react accordingly. Depending on the warning zone and individual configuration, this can be an acoustic signal, a speed reduction or even stopping the vehicle. The system can be easily integrated into existing or new forklift truck solutions and flexibly configured according to individual customer requirements - effectively reducing collisions and impact damage inside* and outside the narrow aisle.

*not in accordance with DIN 15185-2

If desired, you can limit the usage of your forklift truck to specific persons or groups of persons via access authorisation. Select whether the release of the truck should be carried out using a key switch or via a digicode system with ten configurable access codes (or PINs).

Learn more

Digicode systems (PIN) are an easy way to prevent unauthorised use of the truck. The truck can be started up quickly and easily, simply by entering the PIN code. This allows the user to limit access authorisation to specific individuals or groups. It is possible to configure up to ten PIN codes.

More informationThe unit decelerates automatically during the trip if it is approaching the end of the aisle. There are five different options for this:

- With speed reduction at both open aisle ends It is always possible to drive toward the middle of the aisle at maximum speed. From the beginning of the aisle end zone, the speed is reduced to 2.5 km/h.

- With absolute stop: Speed reduction at the open aisle end as well as speed reduction and absolute stop at the closed aisle end. It is always possible to drive toward the middle of the aisle at maximum speed. From the beginning of the aisle end zone, speed is reduced to 2.5 km/h. At the closed aisle end, the unit is decelerated to a halt with the absolute stop. A positioning movement toward the end of the aisle is possible with the acknowledgement button.

- With stop at both open aisle ends. It is always possible to drive toward the middle of the aisle at maximum speed. The unit is decelerated to a halt from the beginning of the aisle end zones. Our technicians can set the parameters for clearance to continue driving at a reduced speed of 2.5 km/h toward the aisle end.

- With stop and absolute stop: Stop at the open aisle end as well as stop and absolute stop at the closed aisle end. It is always possible to drive toward the middle of the aisle at maximum speed. The unit is decelerated to a halt from the beginning of the aisle end zones. Our technicians can set the parameters for clearance to continue driving at a reduced speed of 2.5 km/h toward the aisle end. The unit is decelerated to a halt at the closed aisle end, and a positioning movement toward the end of the aisle is then possible with the acknowledgement button.

- With absolute stop at the closed aisle ends and speed reduction at the open aisle ends. It is always possible to drive toward the middle of the aisle at maximum speed. From the beginning of the aisle end zones, the unit is decelerated at the open aisle end to 2.5 km/h, and brought to a halt at the closed aisle end. The unit is cleared for continued driving using the acknowledgement button to depart the aisle at a maximum speed of 2.5 km/h.

Like driving on feathers:

the shock-protected cab floor relieves pressure from the employee and a large foot pedal allows for a variable and comfortable stationary position.

Learn moreSeeing instead of estimating

With the help of the optional LED lift height sensor (standard on the FM-X), the lift height display ensures maximum precision from the very first millimetre. This means that operators always know the height of the fork tips and can navigate precisely to avoid touching the rack when picking up the pallet. The system works with a repeatability of less than +/- 5 mm and the lift height is permanently shown to the drivers on the display.

Unique around the world: active load stabilisation in narrow aisle operations

Save time during storage and retrieval: heavy loads cause shaking in the MX-X lift heights. This results in a waiting period until the shaking subsides. The optional ASL counteracts this with additional lifting to reduce the shaking and waiting time. It makes work considerably more pleasant and increases the handling capacity by up to 5%. The system enables quick and safe transport movements which are optimally adapted to the lift height and load.

Learn moreNavigation support for the driver The system optimises the approach to the destination by stopping forks automatically at the horizontal and vertical target position. The positioning is worked out by means of distance measuring and comparison with the current position (by RFID transponders or barcodes). OptiSpeed 4.0 differentiates between loading, unloading and order picking at the target position, and adjusts the lifting height of the fork automatically.

Easy to use: manual input of the storage location or retrieval from the warehouse management system; operation at just a push of the drive lever.

High productivity: the truck takes the optimal route to its destination – regardless of the operator’s experience and knowledge.

High precision: the truck moves to the exact position of the pallet – fork movements outside the target are not possible, thus avoiding incorrect storage and retrieval.

Learn more

Smart orientation: forklift trucks which move via inductive forced steering or mechanical forced operation are able to detect if they are in the correct warehouse aisle thanks to the contact-free aisle detection.

Learn moreMaximum handling capacity: STILL OptiSpeed

Comprehensive hardware and software assistance systems which optimise the movements of the equipment regardless of the load. This significantly increases your handling capacity.

With load detection and intelligent load capacity chart for increased handling capacity.

Maximum handling capacity: STILL OptiSpeed

Comprehensive hardware and software assistance systems which optimise the movements of the equipment regardless of the load. This significantly increases your handling capacity.

The system combines the advantages of OptiSpeed 3.1 with a weight sensor: in addition to the visual and acoustic signals when specific limit values are reached, a travel and lift stop is triggered when the permissible load weight is exceeded.

In addition, it calculates ideal transport movements and optimises them based on the lifting height and load.

This enables higher speeds on empty runs or when loading and picking.

Forks up, speed down:

More safety, less product breakage and ensuring proper vehicle use - these are the benefits offered by the Speed Reduction assistance system when the fork carriage is raised. As soon as the forks reach a height of 500 mm (or another defined threshold), the speed of the vehicle is automatically reduced. Even if a driver forgets that he should not drive with the load raised, the assistance system slows him down, guaranteeing safe handling of the load and vehicle.

Learn more

The panoramic mirror, which can be mounted on the left or right side of the truck, improves visibility and reduces the size of the blind spot by expanding the field of vision. Drivers are able to get a quick overview of what’s behind them, allowing them to work more safely.

Downloads

The document provided for download is the updated version of the operating instructions for the standard truck. It does not include descriptions of customer options (Customer Option). For a concrete truck, please request the respective specific manual according to the serial number and the year of production from the STILL spare parts service.

| Model | Maximum capacity (kg) | Maximum lift height (mm) | Travel speed (km/h) | Battery voltage (V) |

|---|---|---|---|---|

| MX-X / Li-Ion | 1.500 | 18110 | 14 | 80 |

| MX-X iGo | 1.400 | 14000 |