Intralogistics consulting

Systematic optimisation for your intralogistics

- Identify the optimisation potential - for warehouses, fleets and processes

- Minimise transport, storage and handling costs

- Identify the automation potential of your logistics processes

- Lay the foundation for lean material supply

We are there for you.

Do you have any questions or would you like personal advice?

Then you've come to the right place. Our team of experts will take care of your request - individually and quickly.

Call a consultant

We are there for you – Monday to Friday

Use the contact form

Write to us – we will get back to you

What happens after sending?

1. You will receive an automatic confirmation by email

2. Your request will be checked by our team of experts

3. You will receive a personalised response within 24 hours

The entry into systematic intralogistics optimisation

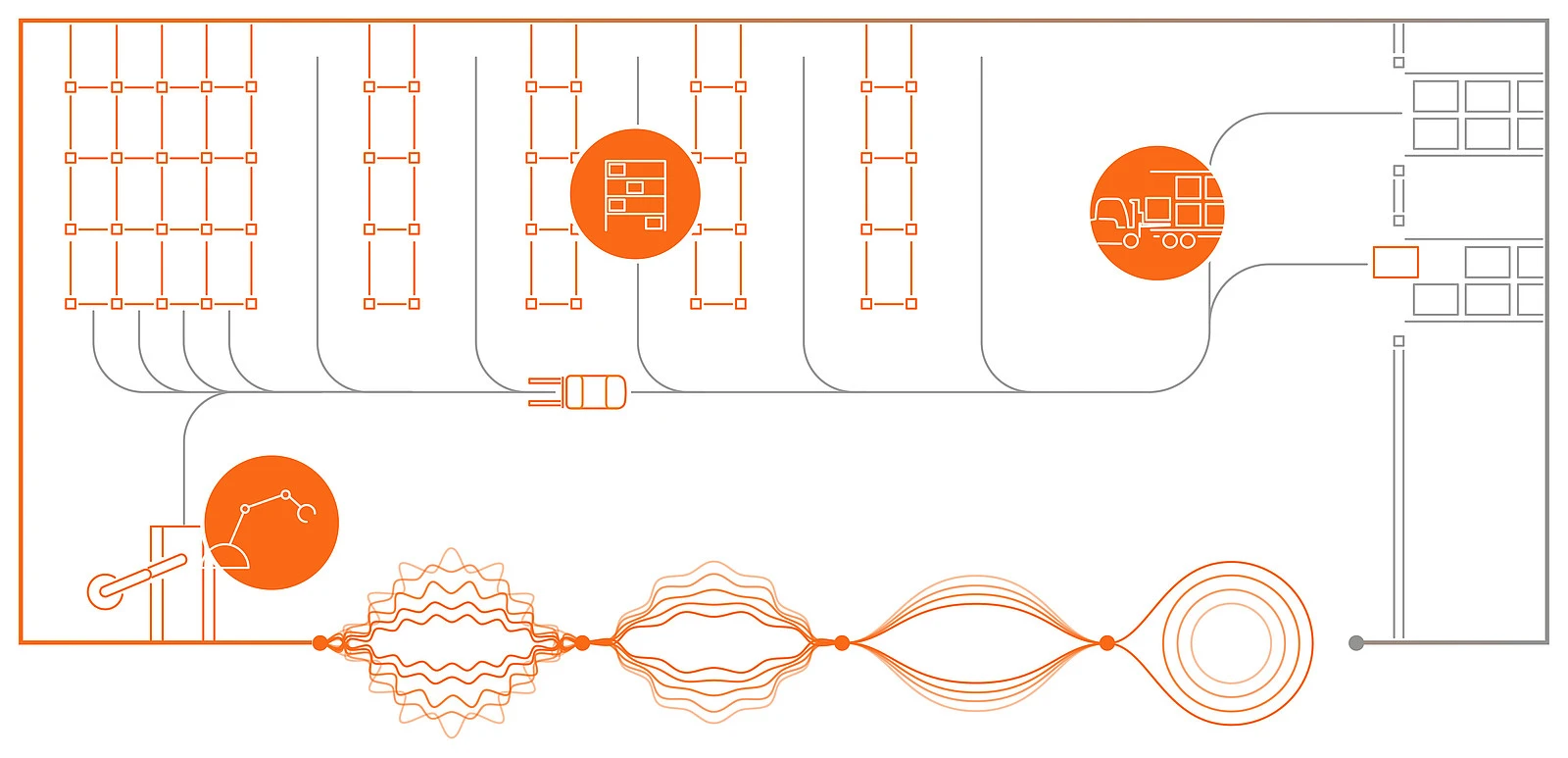

Warehouse planning

Holistic concepts for existing and new warehouse projects

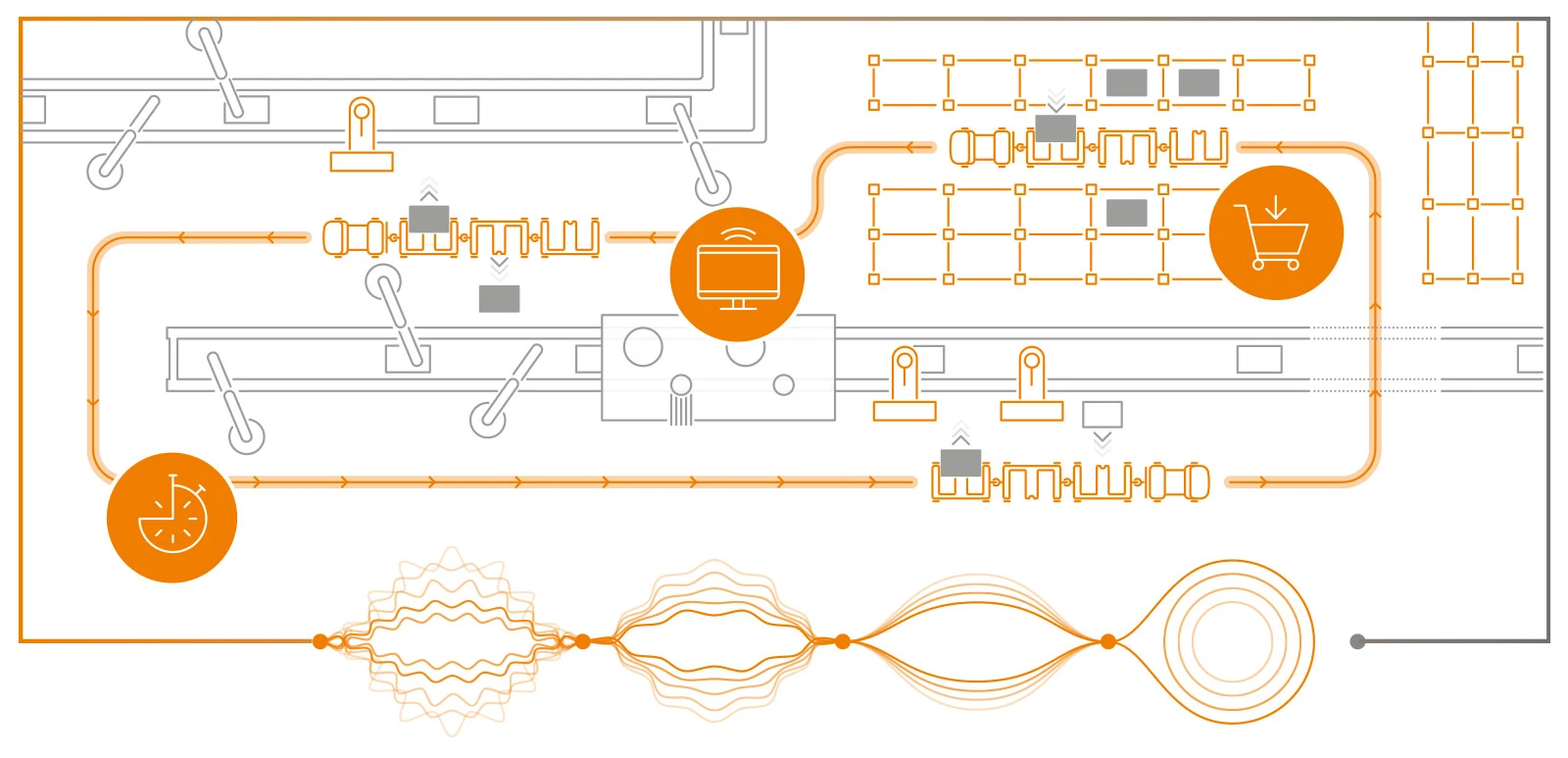

Warehouse planning is holistic and can include different aspects depending on your needs, from the efficient storage of your goods in suitable racking systems, to the transport of goods with suitable industrial trucks, tugger trains and automation solutions, to control using innovative software solutions.

As a result, you receive a holistic warehouse concept for storage, handling, order picking and transport as well as a process description for your material and information flow.

Warehouse consulting

- Warehouse analysis (turnover and inventory analysis)

- Development of different warehouse and transport layouts

- Dimensioning of the warehouse (capacity, stock turnover - and performance)

- Process and layout design

- Transport/material flow concept

- Optional: specification, preparation of tender documents, project implementation

+44 345 603 6827

Request to: Intralogistics Consulting | STILL Germany

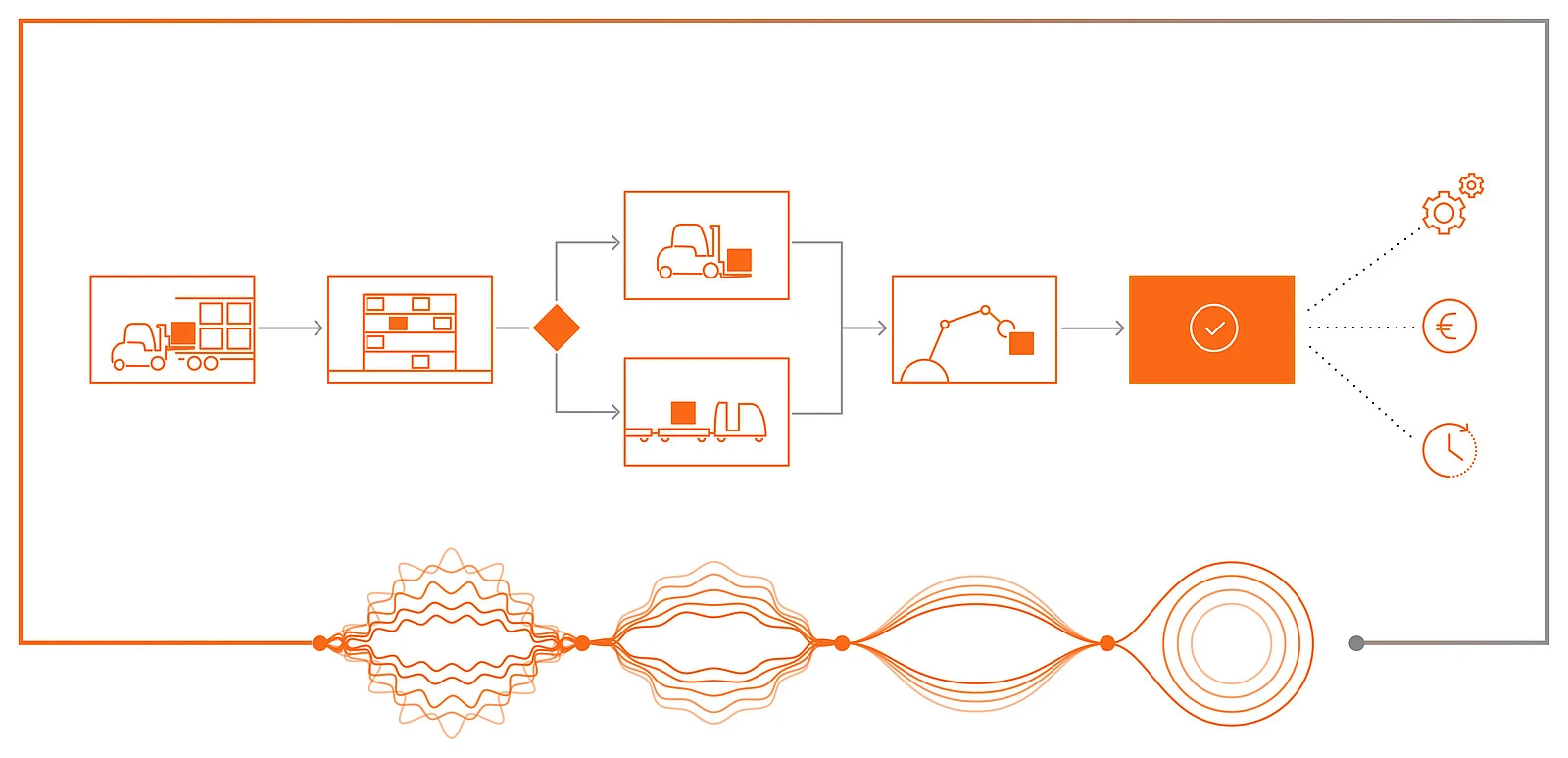

Process optimisation

Your warehouse can do more than you think

After recording the current status of your logistical processes, we identify potential for improvement and evaluate their implementation in practice. In close consultation with you, we create a recommendation for action to optimise the analysed processes and logistical procedures. Analysis and conception are documented in a comprehensible way, the process description is carried out using standardised modelling languages.

Process consulting

- Recording the current state of your logistical processes

- Identification of improvement potentials

- Derivation of suitable measures for implementation

- Concept development and process modelling

- Optional: Requirements catalogue for your IT systems, project implementation

+44 345 603 6827

Request to: Intralogistics Consulting | STILL Germany

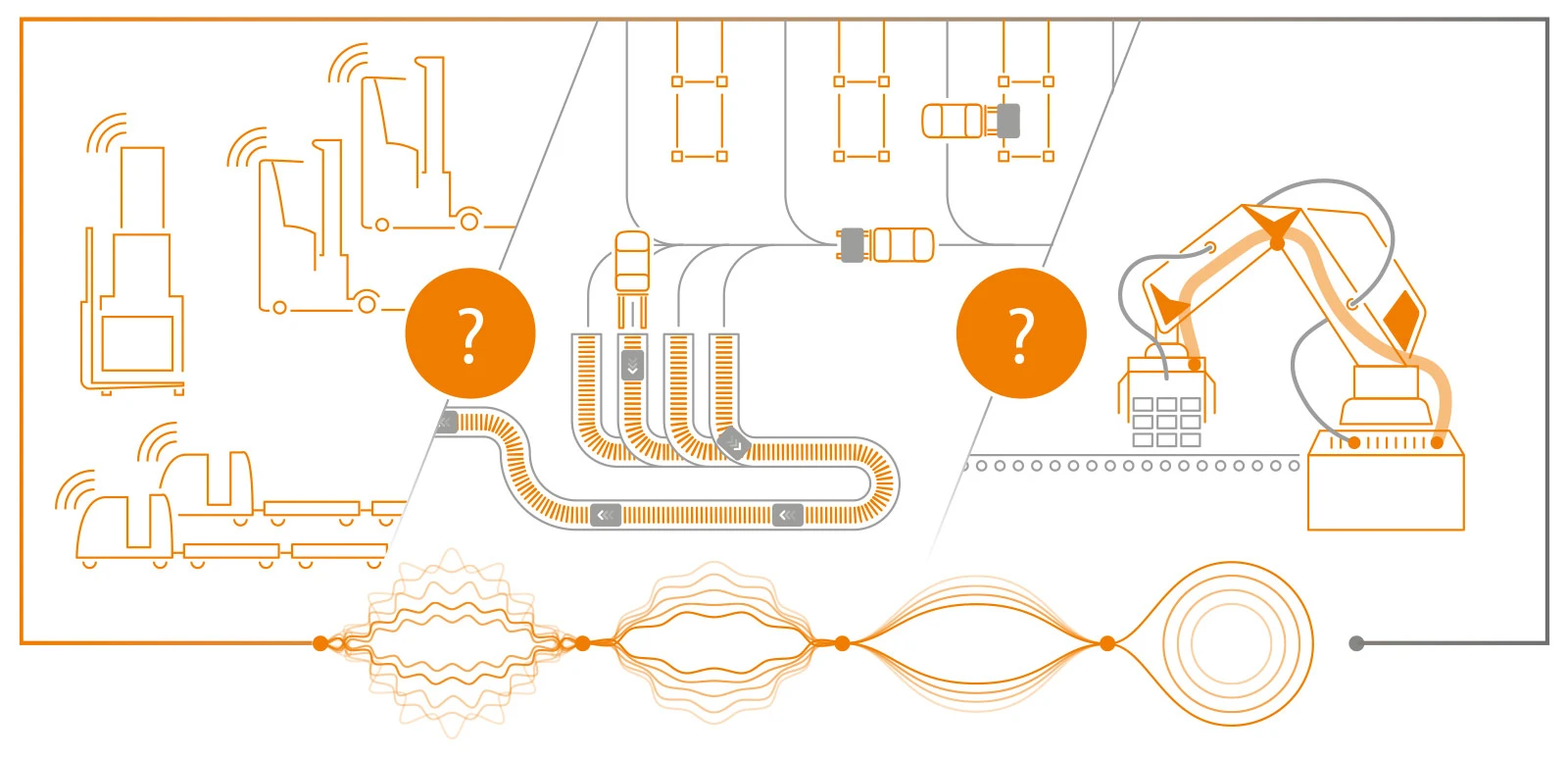

Potential analysis automation

Digitisation for the next level

Automation solutions can be an efficient answer to the growing challenges of digitalisation and to global cost and competitive pressure. But not every level of automation fits every company, not every technology fits every application profile.

Our intralogistics consultancy identifies automation potential in your company and checks the technical and economic feasibility of different automation variants. The analysis identifies obstacles and necessary process adjustments. You receive an individual automation concept and functional specifications as the basis for operational implementation.

Automation consulting

- Determination of automation potentials

- Examination of the technical and economic feasibility of different automation variants

- Automation concept and specification for your automation project

- Optional: Business case development, project implementation

+44 345 603 6827

Request to: Intralogistics Consulting | STILL Germany

Introduction of routine pull systems

Foundation stone for lean production supply

The use of a tugger train system for internal material supply lays the foundation for lean production. The material is delivered and disposed of according to demand, at high frequency, reliably and with minimal traffic. But each tugger train is an individual solution.

Based on an as-is analysis of the material flow and the logistical framework conditions, we develop your individual tugger train concept. We define the elements of your tugger train system - from tractors and trolleys to routes, timing and control. Finally, we design the ideal tugger train process together with you and, if desired, also show possible automation options.

Tug-of-Way Consultation

- Recording of the actual state

- Possible combinations of route train elements

- Possible applications of tugger trains on site Material flow concept with tugger trains

- Optional: Examination of automation levels, project implementation

+44 345 603 6827

Request to: Intralogistics Consulting | STILL Germany

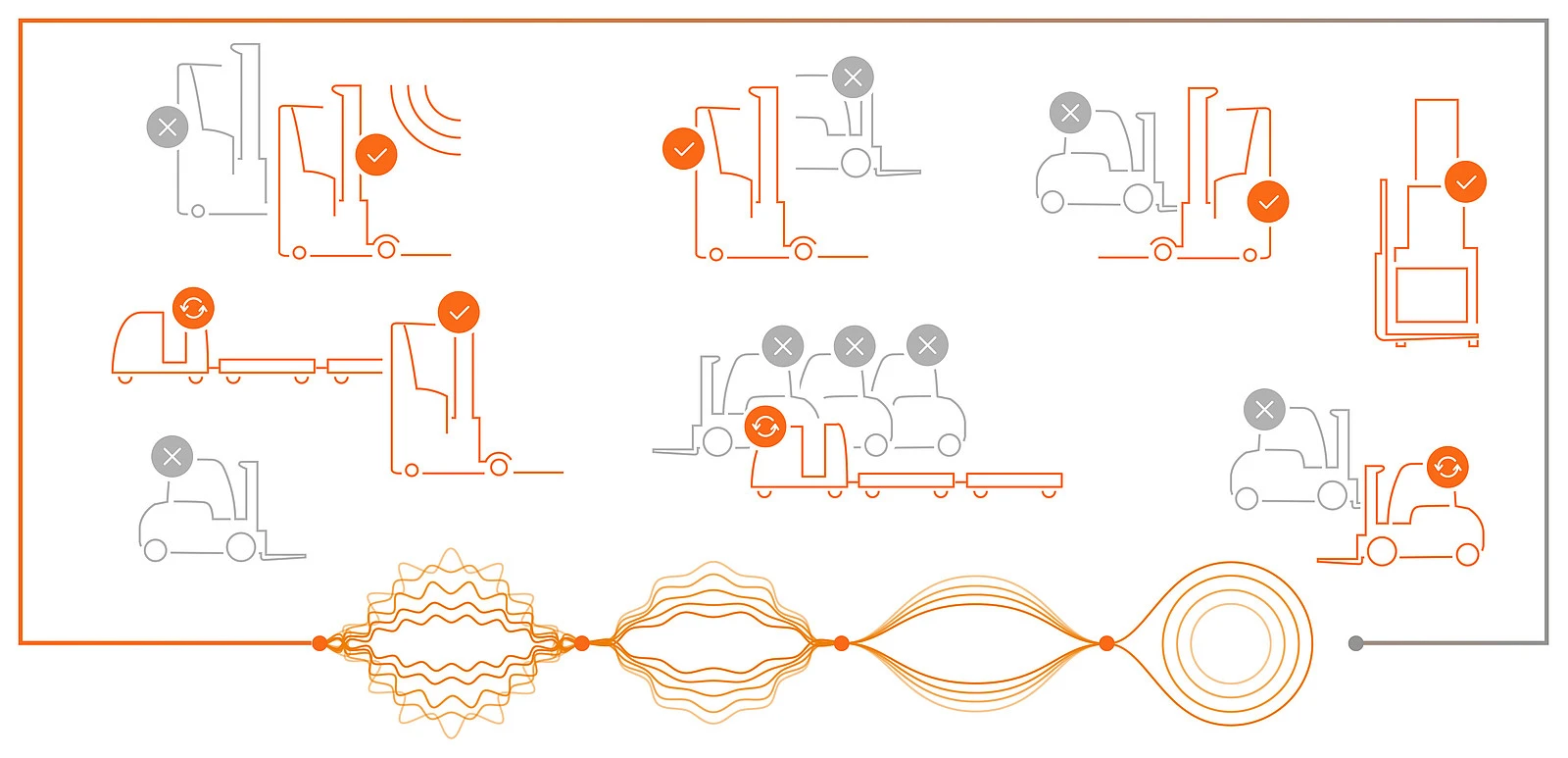

Fleet Optimisation

Getting the most out of your fleet

Fleet optimisation aims to make the best use of your current fleet - regardless of whether you use STILL trucks, trucks from other manufacturers or mixed fleets. We advise on the best possible combination of vehicles and fleet utilisation. You will receive a fleet concept tailored to your needs that takes into account all transport goods, processes and systems.

Fleet consulting

- On-site analysis of fleet utilisation

- Manufacturer-independent consulting

- Action plan and fleet concept

- Optional: concept implementation, testing of automation solutions, potential analysis for the use of tugger trains

+44 345 603 6827

Request to: Intralogistics Consulting | STILL Germany

Intralogistics consultancy from STILL

As an intralogistics expert, STILL can look back on 100 years of experience in warehouse technology, in-plant logistics and forklift truck manufacturing. We only propose solutions that we are convinced can be implemented and will work in the future. Our consultants know no pigeonhole solutions and have many years of experience in intralogistics optimisation. We rely on transparency and trust and drive projects forward at full speed.

Success factors

Transparency: Full transparency: Our clients understand at a glance what the consultant is doing and which approach has been chosen to achieve the jointly defined goal.

Expertise:Decades of experience: Our consultants are industry experts and can optimally implement customer projects with the help of STILL's entire wealth of knowledge.

Solution orientation: Assured feasibility: We always look for the best solution in terms of both modernity and feasibility.

Individuality: Unique results: Our consultants see from your perspective to create original and efficient solutions.

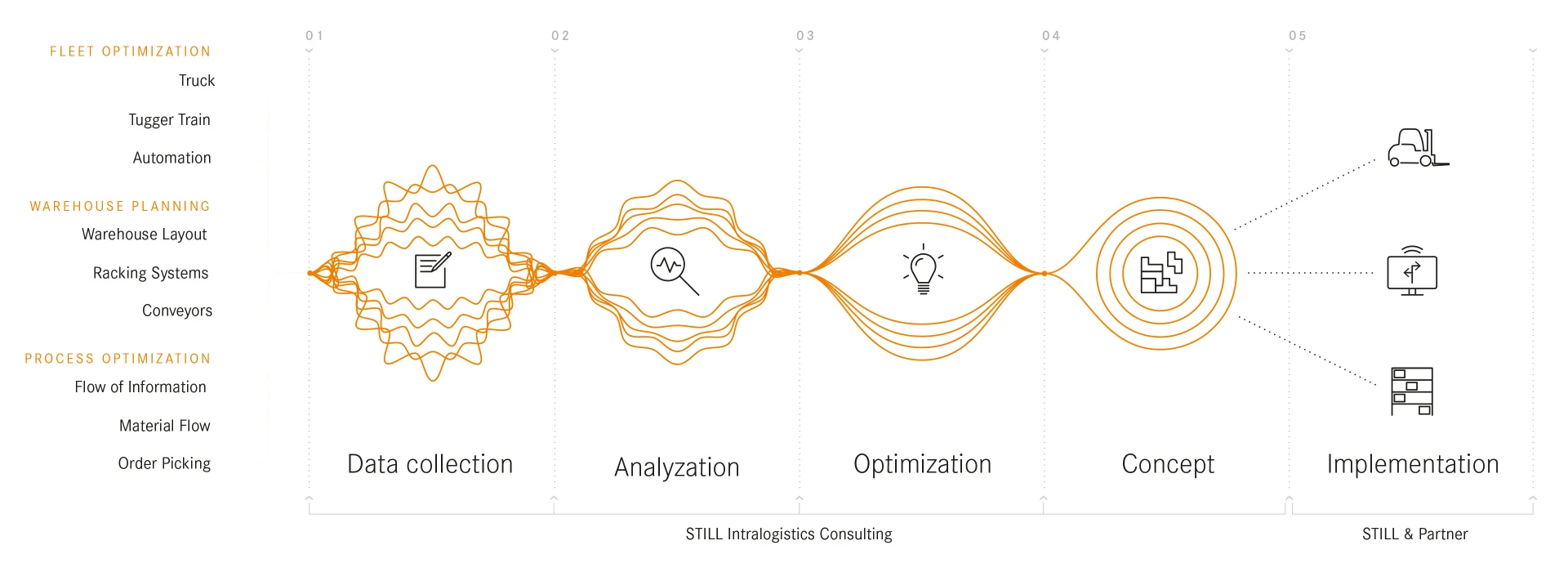

Our path to your solution

1. Data acquisition.

Outstanding analyses are usually based on a high-quality data set.

The success of a project therefore depends to a large extent on the quality of the planning data available. Data collection is therefore of paramount importance. We conscientiously check your data for completeness and consistency and prepare it for subsequent analysis.

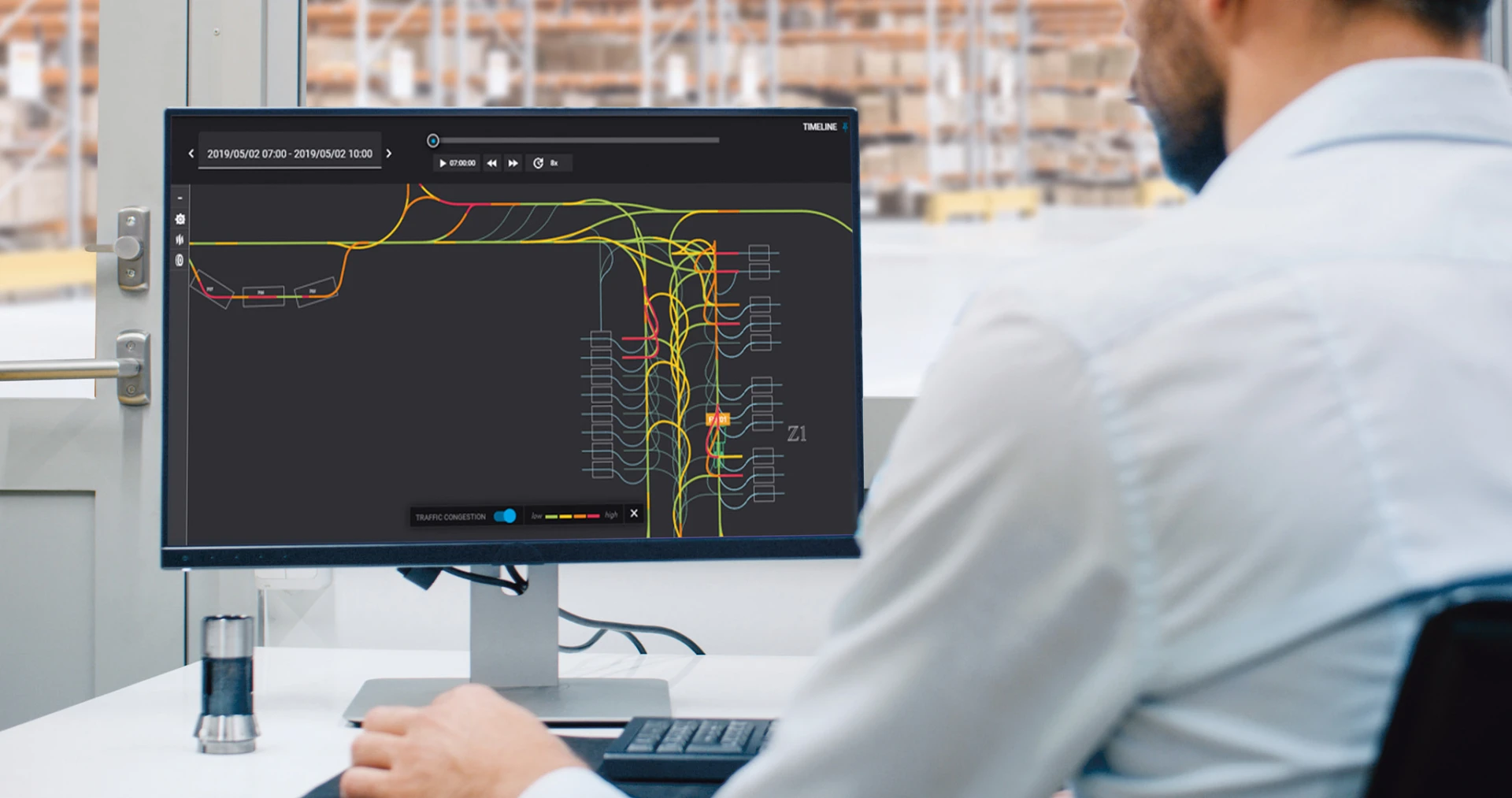

2. Analysis.

To gain logistical insights based on the processed data as a basis for planning, we use techniques such as grouping, sorting, condensing or filtering.

3. Optimisation.

Constant changes in the operational area may require an adjustment of existing systems and processes.

Constant changes in the operational area can make it necessary to adapt existing systems and processes.

4. Concept.

Our goal is to minimise your transport, storage and handling costs.

In order to achieve the necessary increase in efficiency of the logistical systems and material flows, we work out various use cases and solution approaches in close consultation with you. We then check all variants for their economic efficiency and work out the advantages and disadvantages. As a result, you receive an optimal and custom-fit concept. Our consulting services include the selection of suitable racking systems, the development of warehouse layouts and the determination of industrial truck requirements.

Downloads

We are there for you.

Do you have any questions or would you like personal advice?

Then you've come to the right place. Our team of experts will take care of your request - individually and quickly.

Call a consultant

We are there for you – Monday to Friday

What happens after sending?

1. You will receive an automatic confirmation by email

2. Your request will be checked by our team of experts

3. You will receive a personalised response within 24 hours

Use the contact form

Write to us – we will get back to you